Automotive

Automotive applications of thermoformed trays involve the use of specialized plastic trays that are created through the thermoforming process to serve various purposes within this industry.

Electronics

Thermoformed plastic trays are widely utilized in the electrical components industry to support the safe and efficient handling and storage of various electronic parts and specific components.

Medical

In the medical field, thermoformed trays are often designed to securely house surgical instruments, medical implants, and other devices used in operating rooms, clinics, and healthcare facilities.

Plastic Services

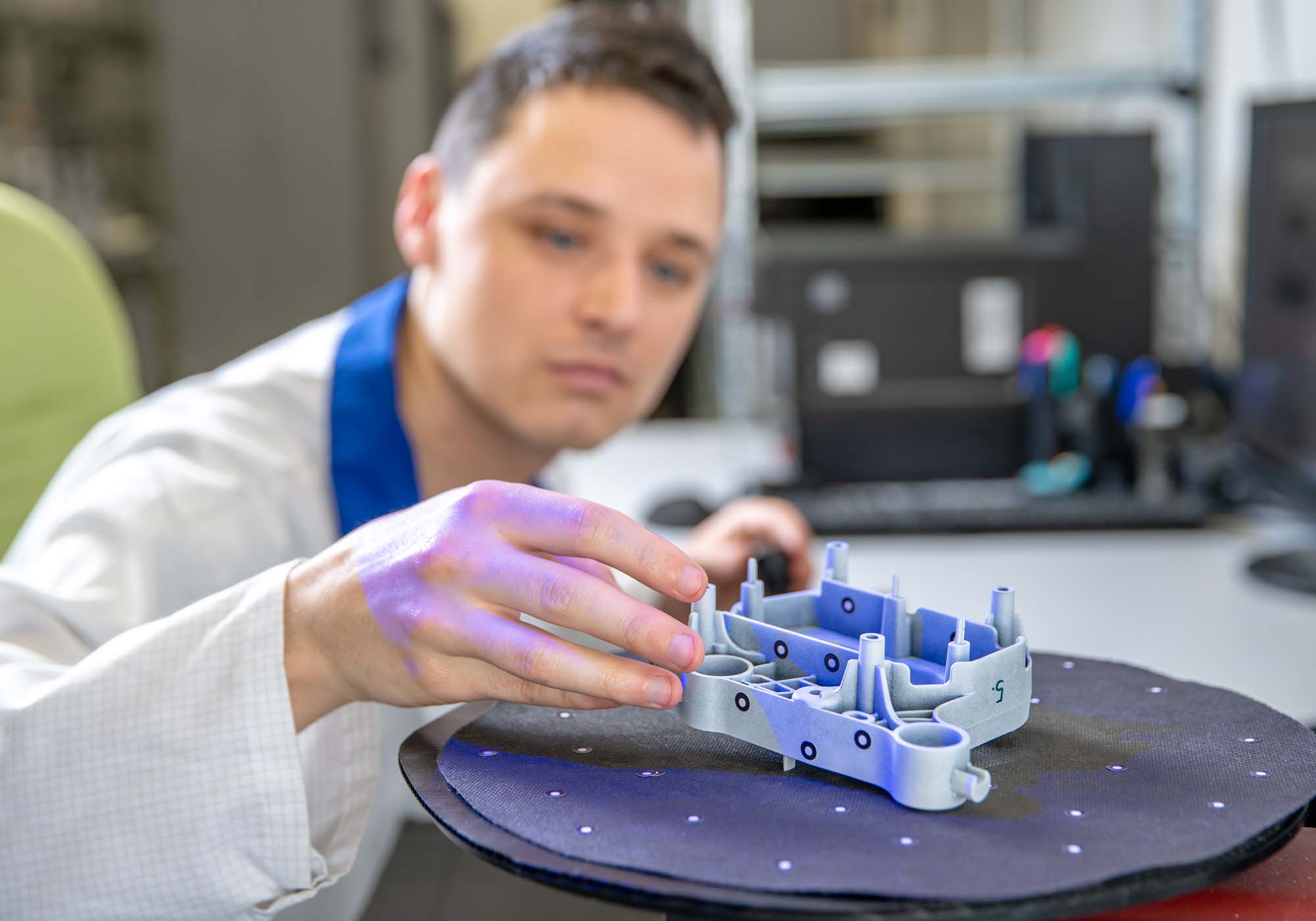

CAD/CAM

CAD (Computer-Aided Design) has revolutionized the creation of thermoformed trays, offering precision and efficiency. CAD software allows designers to craft 2D and 3D models with meticulous accuracy, tailoring the trays to accommodate the specific needs of industries like automotive, electronics, and medical. Customization, cost savings, and streamlined prototyping are key advantages. CAD fosters collaboration among design teams, facilitating client feedback and ensuring a precise match to client requirements. Additionally, it aids in optimizing materials for sustainability, making CAD a vital tool in producing functional, eco-friendly thermoformed trays that meet the demands of diverse applications.

Plastic Services

Prototyping

Prototyping of thermoformed trays is a crucial phase in their development. During this process, a sample tray is created to validate the design and functionality before mass production. Using materials and techniques similar to the final product, prototypes help identify potential design flaws, ensure proper component fit, and assess structural integrity. This step reduces the risk of costly errors in the manufacturing phase. It allows for adjustments, refinements, and client feedback, ensuring the trays meet specific needs accurately. Thermoformed tray prototyping accelerates the development process, saves resources, and guarantees a high-quality final product for applications in various industries.

Plastic Services

Thermoforming

The production of thermoformed trays involves a methodical process in which flat plastic sheets are heated, vacuum-formed, and trimmed to create custom-designed trays. Initially, the plastic sheets are heated until they become pliable, then placed over a mold, and vacuum-sealed to take on the desired shape. Once cooled and solidified, the trays are precisely trimmed and finished. This process ensures trays are tailored to their intended applications, offering protection, organization, and customization. Thermoforming is a cost-effective and efficient production method, widely used in industries such as automotive, electronics, and healthcare for the creation of durable and functional trays.

Customer Support

Need Help? Chat with us on Whatsapp